Aaron split the seat span-wise and bonded the two halves so that they would sit maybe 1/2" to 1" lower than if they were mounted atop the rear spar carry-through, presumably to leave more headroom. The mold at Composites Universal is for a combined back/pan. Therefore it won't work as-is for this application.

Requirements:

- Removable back panel to allow easy access to the rear fuselage area.

- Removable seat pan to allow access to the elevator control stick box and any electronics mounted there.

- Supports under the seat pan and the curve of the back panel so that G-loads are not carried solely by the fasteners.

Design overview (tentative):

- Seat pan

- Cut out the existing pan, leaving 3" around the edges.

- Bond fiberglass flanges around the edge of the remaining seat pan.

- Set the cutout section on the flanges and drill holes for #6 screws.

- Countersink the holes on the cutout section for 100-degree washers.

- Seat back

- Cut out the existing seat back leaving 3" around the edges, remove the hardware, and patch the holes.

- Leave the half-moon section at the top of the back panel as-is to provide some access to the rear fuselage without removing the entire seat back panel. This is necessary if we go ahead with placing an O2 tank in the existing mounting brackets because the forward receptacle for the tank is integral to the seat back panel.

- Bond fiberglass flanges around the edge of the remaining seat back and add mounting hardware as described above.

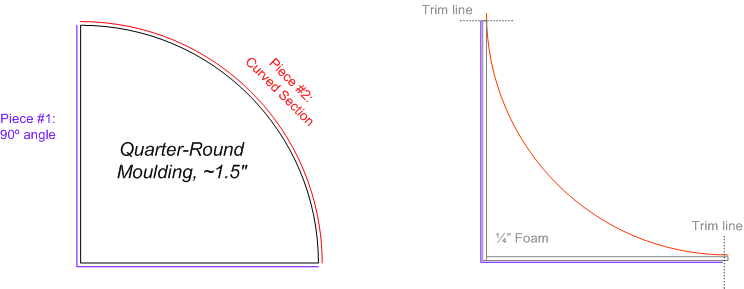

- Add two parallel vertical "rails" to the cutout section, 15" apart per Allen Silver, formed like this: