From the Extra 300/L Service Manual:

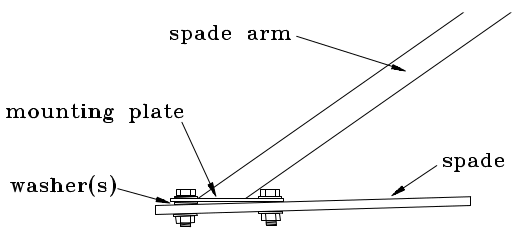

For roll trim the spade rigging angle of incidence has to be changed. Insert washer(s) between the spade and the mounting plate. For example: When the aircraft rolls to the left, insert washer(s) at the front attachment bolt of the right spade.

From Doug Sowder:

The technique is shown in section 27 of the Service Manual available for download on extraaircraft.com under Service and Parts / Tech Service. It's easiest to work with the single front bolt on the spade mounting plate. If the plane rolls right, you want the LEFT spade to "dig" a bit to push the LEFT aileron UP, so add a thin shim between the LEFT spade and the front of the mounting plate. The ailerons are extremely effective, and even though they look neutral, a nearly imperceptible difference can make the plane roll. I found that even the "L" (thin) -3 washers are too crude for the small adjustments that are necessary, so I trace around a coin on shim stock, cut a washer out with snips, and punch a hole in the middle. I've used shims as thin as .002" to get it right, along with some adjustment of the tightness of that front bolt. I haven't tried using a nylon washer there as Mike suggested, but that would facilitate making small changes just using bolt tension.

Before getting too carried away, check to be sure that your rudder is neutral, perhaps even checking the bank ball to be sure that it's level in the instrument panel. Since rudder requirement varies with power, speed, and angle of attack, you want to hold the ball centered with pressure on the pedals when checking for rolling tendency.